FT-S1 Single stepping Motor, Intelligent lockstitch Sewing Machine

| Min-Max Sewing Speed | 200-5000 (Sti/Min*) |

| Power consumption | 320V |

| Bobbin Thread Winder | Yes |

| Max. Stitch Length | 0-5mm |

| Lift of Presser Foot | by hand: 5.5mm by Knee: 13mm |

| Needle Type | DBx1 11-18# |

| Needle Bar Stroke | * |

| Feed Dog height | * |

| Needle Positioning | Yes |

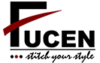

| Lubrication | Automatic |

Get in Touch! Reach out using the info below or fill out the form. Let’s connect with our Expert within 10 Minutes!

Contact With Our Team

Product Description

Pattern seam control: The stepper motor regulates the needle’s movement or fabric feed to create consistent and repeatable patterns.

Rice grain stitches: These are likely small, oval or elongated stitches resembling rice grains, commonly used in decorative stitching or specific textile applications.

Stepper motor: Provides precision control, enabling the machine to switch between different stitch types seamlessly.

1-9 Stitch options: Refers to the ability to select from up to 9 different rice grain stitch patterns, which might vary in length, density, or directionality.

Reverse stitching ultra-quiet: This feature refers to the sewing machine’s ability to perform reverse stitching (backstitching) with minimal noise. This is particularly important for environments where noise control is critical.

Cloth feeding: The fabric is smoothly fed into the machine, either forward or backward (for reverse stitching), ensuring that the stitch placement remains accurate and consistent.

Sound is light: Indicates that the machine operates with reduced noise levels, likely due to high-quality materials, motor insulation, or precision engineering, which minimizes mechanical noise.

Stable feeding: A smooth, reliable feed mechanism ensures that the fabric moves through the machine without skipping or pulling unevenly, which is crucial for producing consistent stitches, especially during reverse stitching.

Note: This feature would be beneficial in professional sewing applications where both precision and quiet operation are necessary, such as in offices, workshops, or when sewing delicate fabrics.

Tight seam function: This feature helps to create a secure and clean finish to the seam, pulling the threads tight to avoid loosening or fraying. It ensures that the stitches are firm and the seam is neatly finished.

Short thread head: Refers to the small length of thread remaining after the thread is cut. In this case, the system is designed to leave very short thread ends.

Thread length less than 3mm: After the machine trims the thread (either automatically or manually), the remaining thread on the fabric is less than 3 millimeters long. This ensures a clean and professional finish with minimal thread tails, reducing the need for further manual trimming and preventing loose ends from sticking out.

Note: This function is ideal for applications where a clean and polished look is essential, such as in garment manufacturing, high-end fashion, or detailed sewing projects where neatness and precision are prioritized.

Intelligent feeding mechanism: Refers to an automated system that adjusts fabric feeding based on the machine’s programming or settings, allowing for fine control over the stitching process.

Controlled by the stepper motor: The stepper motor provides precise, incremental control over the fabric feed, offering higher accuracy than traditional mechanical feeding systems. Stepper motors allow for exact positioning, making the fabric feed smooth and consistent.

Precise feeding stroke: The stroke (the movement of the fabric through the machine) is carefully calibrated for uniformity, ensuring that the stitches are evenly spaced. This precise movement is particularly important when switching between forward and reverse stitching.

Reverse seam coincidence: This refers to the reverse stitching (backstitching) perfectly aligning with the forward stitches. When reverse stitching is used to reinforce a seam, the alignment between the forward and reverse seams ensures durability and a neat appearance.

Note: This feature would be valuable for high-quality sewing, where precision is critical, such as in industrial garment production or detailed, custom work.

# FT-S1 Features

| 1. Stepping Motor | 2.Auto Needle Positioning |

| 3. LED Control Panel | 4. Advance LED Light |

| 5. USB Port | 6. Stitch Length Adjustable |

| 7. 9 Kinds of Patters | 8.Auto Lubrication |

| 9. Auto Thread Wiper | 10. Bobbin Winder |

| 11. one key click restored | 12. Needle Guard |

Product Technical Specification

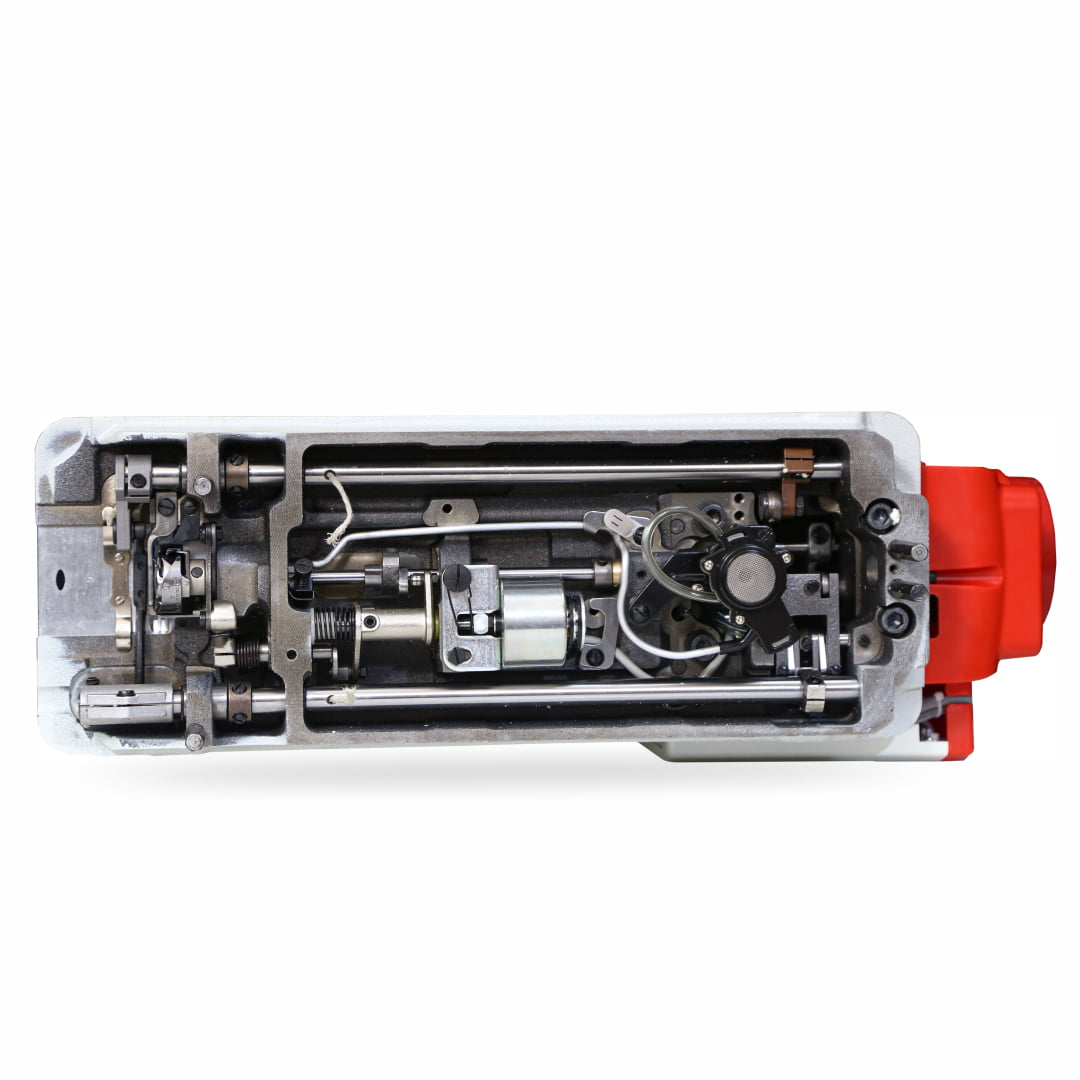

LED Control Panel

LED control panels enable operators to customize settings like stitch length, speed, and tension, granting them precise control over the sewing process. This flexibility empowers users to adjust settings according to the fabric type or specific sewing task at hand, optimizing efficiency and quality in their work.

Oil Window

oil window is a small transparent or translucent section usually located on the body or casing of the machine. Its purpose is to allow the user to visually inspect the level of oil inside the machine’s lubrication system.

Restore Key

Voice guidance/one-key reset: Real-time broadcast of multi-language voice, one key click restored.

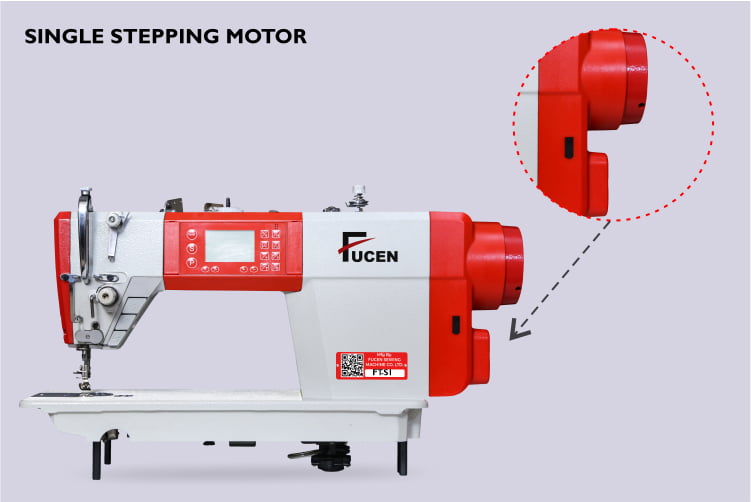

Single Stepping Motor

single stepping motor, also known as a single-phase stepping motor, is a type of electric motor used in various applications, including in sewing machines.

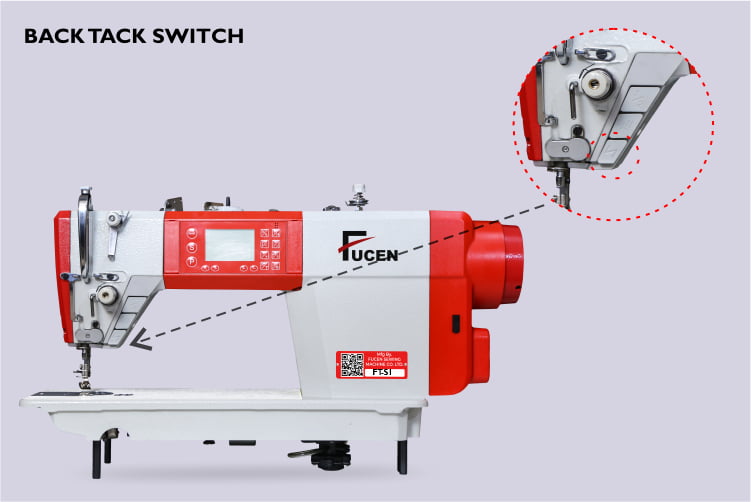

Back Tack Switch

Back tack is a term commonly used in sewing, particularly in the context of sewing machines. It refers to a stitching technique where the sewing machine sews a few stitches in reverse at the beginning and/or end of a seam. This technique is also known as backstitching or reverse stitching.

Download Catalog For FT-S1

FT-S1 Single stepping Motor, Intelligent lockstitch Sewing Machine

Get Quote !

Need help? Call our award-winning support team at +91-9811002015